The Client

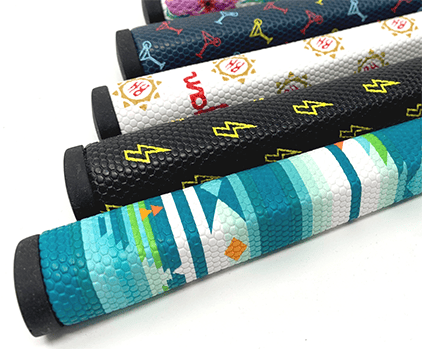

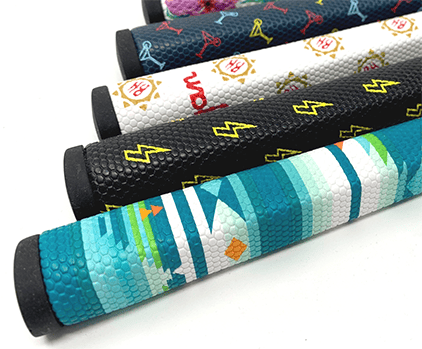

A new company with a new idea, to revolutionize the golf club grip industry, by developing an ultra performance grip with cutting edge graphics and designs embedded right into the grip. The most stylish grip available, with over 40 graphics to choose from, our client was looking for a solid supply partner that had experience with high end printing technology and custom rubber injection molding. IPS was chosen because of our ability to locate and contract never before used factories for this type of production.

The Task

Our client had found some factories that claimed to be capable to produce such a product, but could not execute. They had spend over a year developing their product with other suppliers, only to be disappointed in the results. Their business plan was ready, but they were lacking good quality product at reasonable costs to make it all work.

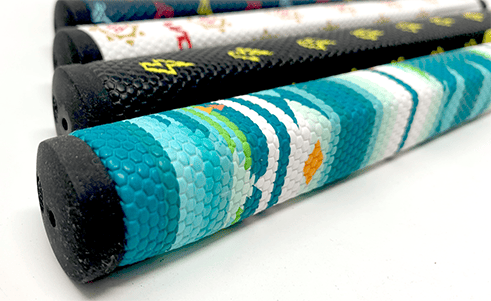

- Printing Tech: Contract and develop a new type of printing that could be applied to a golf grip consistently and with durability.

- Quality Manufacturing: Locate and contract consistent factory base partners with the ability to work with us to grow the business.

- Budgetary Concerns: Proper planning and engineering was would be needed to control costs to keep the final product within budget and industry standards.

Design work and client interface conducted in USA, with factory management, engineering and quality control handled in our Taiwan office. Final production and assembly in Taiwan, with components and packaging from mainland China.

The Process

Once handed over to IPS, we re-engineered the grip to utilize material changes required to product the new golf grip to specifications. New printing processed and technologies were tested and brought online to produce grip samples like never before seen. Field testing was conducted with 100 grip samples, and modifications were made to generate a final consumer ready product within 90 days of starting development. New graphics were created and refined by our in-house graphics team to provide consistency across all grip graphics, logos and packaging. Within 120 days of start, we were in production on the first order of grips which were a huge success in the market. Since then, we have helped develop and deliver additional shapes and size golf grips, with 40 different styles with thousands of grips produced to date.

Challenges We Overcame

This project presented a couple of key challenges, including:

- New technologies: We needed to find and contract new factories and develop new printing technologies

- Material engineering: Standard grips utilize polyurethane foam cores, while this client wanted a higher end natural rubber material.

- Tooling & design engineering: New injection molding needed to be created within set budgets and with multiple new features. Grip designs needed to be completed and engineered to utilize the new printing technologies and core material changes.

- Budget: As with many of our projects, final unit pricing is always a concern. With strict budgetary constraints, these challenges were magnified requiring alternative production line configurations and sourcing considerations.

Results

The customer continues to work with IPS for new grip product and also additional line extensions to broaden their offerings to consumers. As their “one stop shop” for all their consumer product development and production needs, we have simplified their business operations which have allowed them to focus on the front end marketing and sales operations to grow their company.