Diverse Client Needs:

At IPS, every project kicks off with a complimentary consultation because your unique product deserves a tailor-made approach. We want the lowdown on where your idea stands – whether you’ve got CAD files, patent sketches, material preferences, or even a working prototype. If you haven’t sorted these details yet, no sweat – we’ve got your back.

The level of upfront work our team needs to move your idea from concept to manufacturing depends on its current status. We collaborate with clients in different stages of the ideation process, from those in the initial ‘napkin sketch’ phase to those with detailed engineering schematics and functional prototypes. Most often, our clients fall somewhere in between.

Once we know what services your product requires to be ready for manufacturing, we’ll suggest the most suitable development package for you.

Our goal is to become your main and only manufacturer…we do this through superior product development and manufacturing services for our clients.

Compensation Structure:

Development Phase (1):

The first step for out clients is the development phase where we help design and engineer the product idea. The primary objective of the development process is to articulate a comprehensive “blueprint” aligned with our clients’ product vision. This multifaceted process encompasses ideation sessions, concept creation and documentation, engineering and CAD work, prototype and field testing, identification/negotiations with suitable factories, as well as cost assessment and estimates. This comprehensive undertaking demands both time and financial resources.

As part of our commitment to our client’s success, we offer these services as a “pass-through” cost, devoid of any additional markup or margin. Prior to embarking on any project, we engage in detailed discussions with our clients regarding the anticipated costs associated with the development process, ensuring transparency, and avoiding any unforeseen surprises. Ultimately, our objective is to evolve into the ultimate supplier for the products we assist in developing, as this is the sole avenue through which we derive profit from any project.

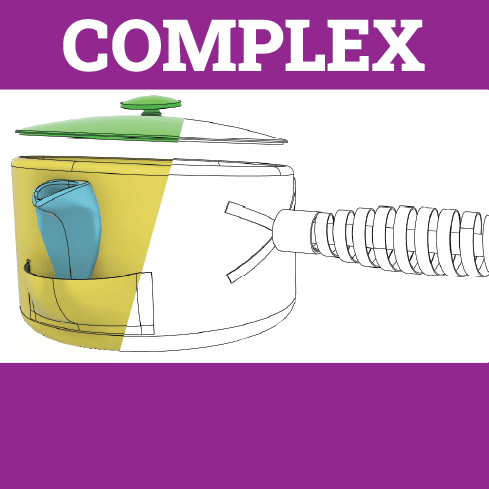

Because each product we work on is different, the development phase estimated costs are quoted on a “case by case” basis. Quick and easy products can be as simple as 10 hours or less of development, and complex products can be more than 200 hours.

IPS provides total cost estimate to design and develop your product.

Quote Phase (2):

After developing your idea, we move into the “quoting phase” where we work with our factory partners in China, Taiwan and Vietnam to explore the costs associated with producing and importing your product. IPS handles factory selection and negotiations to find the perfect source for manufacturing. We then compute all the costs associated with production and provide our clients with an “all in” unit cost to mass produce their product at one of our partner factories. Pricing includes factory inspections, ongoing quality control, cost of production (per unit), factory compliance measures, transportation to final destination (including import fees) to our clients warehouse. Having a dependable unit price for their globally sourced product allows our clients to plan their business and sales efforts with certainty.

IPS provides “Per Unit Cost” for your product to be mass produced.

Production and Import Phase (3):

Ready to start manufacturing your product ?? The production phase draws on our 25+ years in the contract manufacturing industry. We have been sourcing product in Asia for a long time. We know the problems that can and do happen when managing production on the other side of the globe. We only work with factories we have personal relationships with. Our employees travel to and visit our factories before, during and after production to insure everything we produce exceeds the design and production standards we develop for each product. Our factories are our partners, and we only work with fully inspected and monitored production facilities where worker safety and conditions are prioritized. We produce 100’s of different products with millions of units in volume each year which gives us buying power and production priority with our factories, which we pass along to our clients.

IPS includes a small fee in each “Per Unit Cost” for each unit delivered.