The New Supply Chain Reality: How SMB Brands Can Navigate China+1, Factory Leverage, and IP Risk

Published by International Product Solutions (IPS)

For product development teams, sourcing directors, and brand managers at emerging consumer brands

Introduction: The Procurement Paradigm Has Shifted

The world of global sourcing is experiencing a fundamental shift. What worked in 2015—or even 2019—no longer holds up in 2025. Between rising U.S.–China tensions, global supply chain fragmentation, and increasingly complex regulatory expectations, small and mid-sized consumer brands (SMBs) are being forced to navigate a far more turbulent procurement landscape.

Unfortunately, these brands are the most vulnerable.

Unlike the conglomerates, SMBs typically lack:

- Dedicated sourcing offices in Asia

- In-house compliance and legal teams

- Volume leverage with large factories

- Established relationships outside of China

If you’re a sourcing manager or operations director at an SMB consumer brand, you’re probably asking:

- How do we move production out of China without sacrificing quality?

- How can we get favorable pricing when our volumes are small?

- How do we protect our designs from getting knocked off overseas?

At IPS, we’ve helped dozens of small and medium consumer brands solve these exact problems. In this post, we’ll break down the three most urgent procurement challenges for SMBs today—and how to overcome them.

Challenge #1: The China+1 Imperative

The days of “China or bust” are over. For SMBs, that’s both a threat and an opportunity.

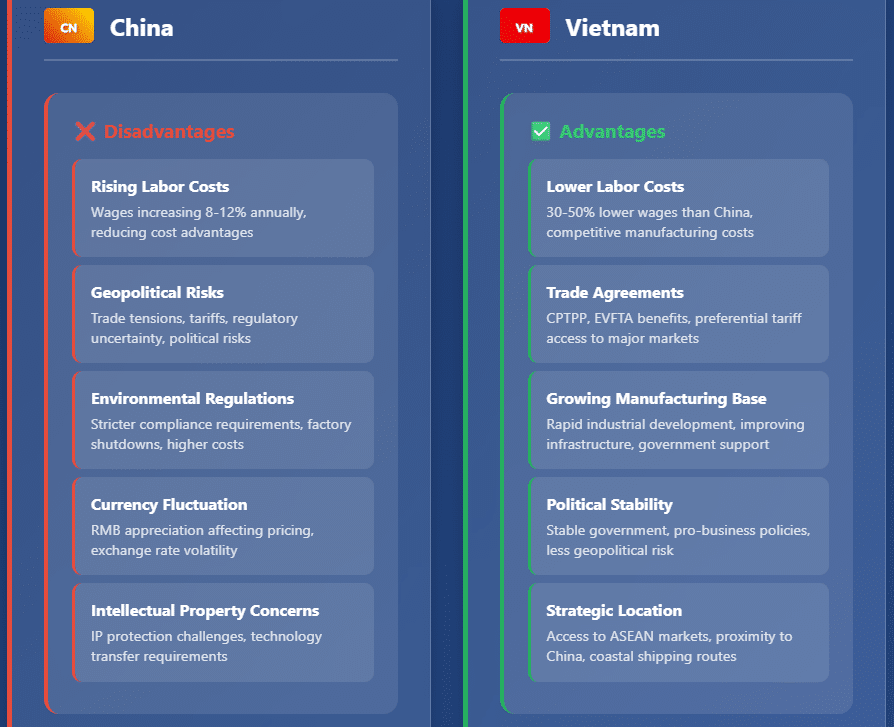

Why Brands Are Leaving China

The reasons are clear and mounting:

- U.S. tariffs on Chinese-made goods remain elevated and unpredictable

- Geopolitical risk—including tensions over Taiwan—creates uncertainty

- Labor and compliance costs are rising in coastal China

- Western retailers increasingly pressure suppliers to diversify their sourcing base

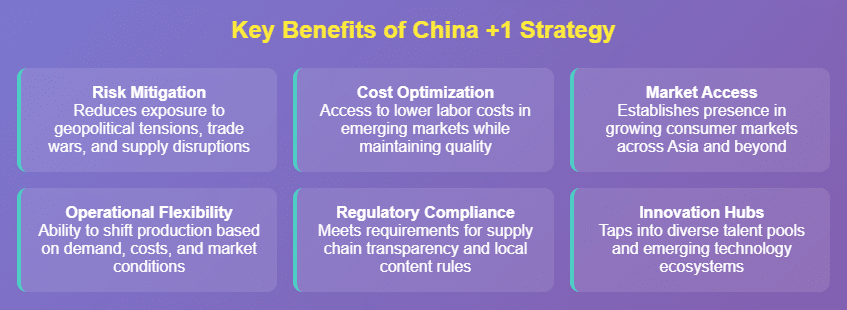

This has given rise to the China+1 strategy—where brands maintain some capacity in China, but shift part (or all) of production to other countries like Vietnam, Cambodia, Thailand or Taiwan.

Why It’s So Hard for SMBs

For smaller brands, shifting out of China presents a major logistical and strategic challenge:

- They don’t know which factories to trust in Vietnam or Cambodia

- They lack in-country teams to audit and manage suppliers

- They fear lower quality or missed timelines in new regions

- Local support networks are weaker, especially without a large corporate presence

And worst of all? Many SMBs have fallen victim to scams or underperforming vendors after trying to relocate too quickly.

How IPS Solves This

At IPS, we’ve already built the trusted network so you don’t have to. Our China+1 strategy includes:

- Vetted factory partners in Vietnam, Cambodia, Thailand, Taiwan

- In-country engineering and sourcing teams that conduct site visits

- Side-by-side cost and risk analysis to compare new vendors

- Ongoing production oversight, including QC, compliance, and packaging review

👉 Learn more about our sourcing and contract manufacturing services.

We ensure that small brands don’t end up compromising on quality or reliability when they relocate.

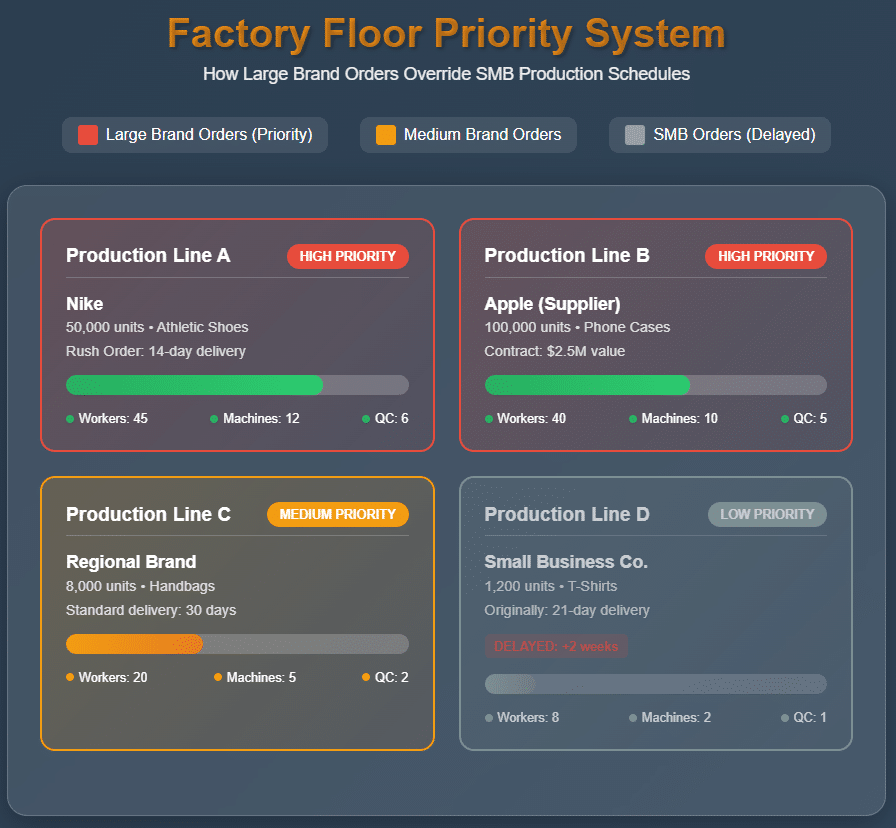

Challenge #2: Lack of Leverage with Offshore Factories

Even in the best of times, smaller order volumes create challenges. But in today’s post-pandemic production environment, the situation is worse than ever.

The New Reality for Small Buyers

Large manufacturers are prioritizing bigger clients who can:

- Consistently place container-load quantities

- Tolerate longer lead times and price fluctuations

- Pay upfront or operate on tighter payment terms

- Invest in custom tooling and long-term volume commitments

That leaves SMBs struggling with:

- Rejected RFQs or ghosting from factories

- Higher unit pricing compared to bigger brands

- Less favorable payment terms

- Longer wait times for sampling and production

Worse, the boom in reshoring/nearshoring interest means competition for factory space in Vietnam, Cambodia and Thailand is tighter than ever.

The IPS Advantage: Buying Power Without Scale

Here’s the difference when you work with IPS:

- We pool demand across clients and pass on economies of scale

- Factories prioritize our business due to our long-term, multi-project relationships

- We offer consolidated shipments, shared MOQ strategies, and multi-product orders

- Our factory partners trust us to manage and grow smaller accounts

This means SMBs can get the benefits of big-brand sourcing without being a big brand.

“One of our clients was getting ghosted by suppliers for months. After moving to IPS, they were in production within 6 weeks with better pricing and upgraded packaging.” – IPS Account Manager

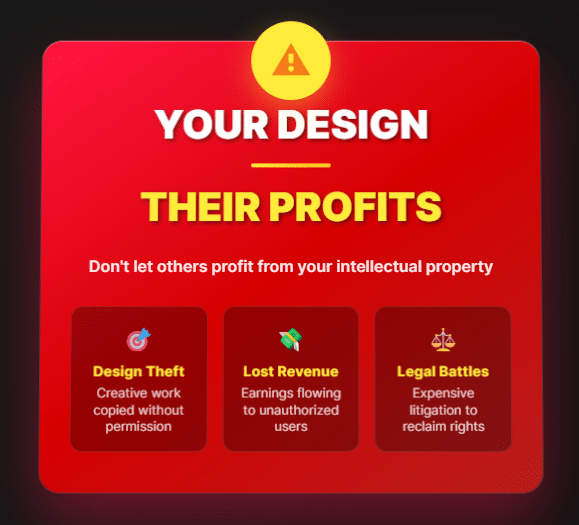

Challenge #3: Intellectual Property Risk in Emerging Markets

Relocating production introduces a new layer of risk that many procurement managers overlook: intellectual property protection.

The Hidden IP Risks

In countries like Vietnam, Cambodia, or India, legal enforcement mechanisms are weaker than in China (which, despite its reputation, has built up strong IP courts in recent years).

The risks include:

- Knockoff products sold through grey markets or online retailers

- Design leaks to competitors or secondary vendors

- Unauthorized production runs that dilute your brand value

- Tooling or molds being reused for other customers

For innovative consumer brands—especially those with patented or design-protected products—this can be devastating.

IPS Has Built-In IP Safeguards

We treat your intellectual property like our own. Here’s how we help:

- All factories must sign non-disclosure agreements (NDAs) and non-compete clauses

- We handle tooling custody, with contracts stating your exclusive rights

- Our sourcing is done through closed-loop vendor relationships, not job shops

- We regularly conduct surprise audits and inspections to ensure compliance

- We store and manage all product specs, artwork, and designs in secure client portals

We also help you register patents, trademarks, and industrial designs in relevant jurisdictions to build a legal shield around your IP.

👉 Contact us to learn how we protect your designs globally.

What Procurement Managers Should Do Next

If you’re managing sourcing or procurement for a small to mid-sized brand, these three challenges—factory relocation, low order leverage, and IP vulnerability—are now mission-critical issues.

Waiting until something breaks is no longer an option.

Here’s how you can get ahead:

- Audit your current supply chain exposure – Where are your biggest risks? Tariffs? Capacity? Copycats?

- Evaluate alternate production regions now – Don’t wait for your factory to drop you or prices to spike.

- Document your IP ownership and lock it down – Get NDAs, register designs, and work with a partner who takes it seriously.

- Partner with a sourcing and production team that can help you scale without scale. That’s where IPS comes in.

Why IPS Is the Right Partner for SMB Procurement Managers

For 25 years, International Product Solutions (IPS) has been helping small and mid-sized consumer brands:

- Design and engineer new products

- Find trusted, verified factory partners across Asia and Latin America

- Manage production, compliance, packaging, and shipping

- Safeguard their intellectual property every step of the way

We know that SMBs don’t have time or money to waste. That’s why our services are structured to give you enterprise-level capability without enterprise-level overhead.

> Verified factory network in China, Vietnam, Cambodia, India, and Mexico

> English-speaking account managers + bilingual sourcing teams

> In-house engineering, design, and compliance support

> Custom-branded portals for your team to track progress

> Strict IP protection policies and tooling management systems

Let’s Talk About Your Supply Chain

Whether you’re looking to move production, find a more reliable partner, or finally protect your IP at scale — we’re ready to help.

Schedule a consultation with our sourcing team today.

Visit our website for more about IPS’s capabilities.

Want more articles like this? Subscribe to our monthly insights newsletter for sourcing managers and product developers.

Follow us on LinkedIn for updates and sourcing tips.