Exploring the benefits of Custom Manufacturing

In the world of product development, custom manufacturing holds a unique position. It’s a process that allows businesses to create products tailored to their specific needs.

This approach differs significantly from mass production. It offers a level of flexibility and personalization that’s hard to match.

But what exactly is custom manufacturing? How does it work, and what benefits does it offer?

In this article, we’ll explore these questions in detail. We’ll delve into the intricacies of custom manufacturing, from the design process to the final product.

Our aim is to simplify this complex concept, making it accessible to startup founders and business strategy consultants alike. By the end, you’ll have a clear understanding of custom manufacturing and how it can be leveraged for business growth and product development.

Understanding Custom Manufacturing

Custom manufacturing involves creating products based on individual specifications rather than a one-size-fits-all approach. This method allows companies to design and produce items that cater precisely to their clients’ needs.

Unlike standard mass production, custom manufacturing emphasizes personalization and adaptability. Businesses leverage this process to craft unique offerings, enhancing their market position and customer satisfaction. By focusing on custom solutions, companies can better respond to evolving consumer demands and carve out a distinct niche in the marketplace.

The Custom Design Process

The custom design process begins with a detailed consultation. Here, clients discuss their visions, specific needs, and design preferences with the manufacturer. This initial step ensures everyone is aligned in purpose.

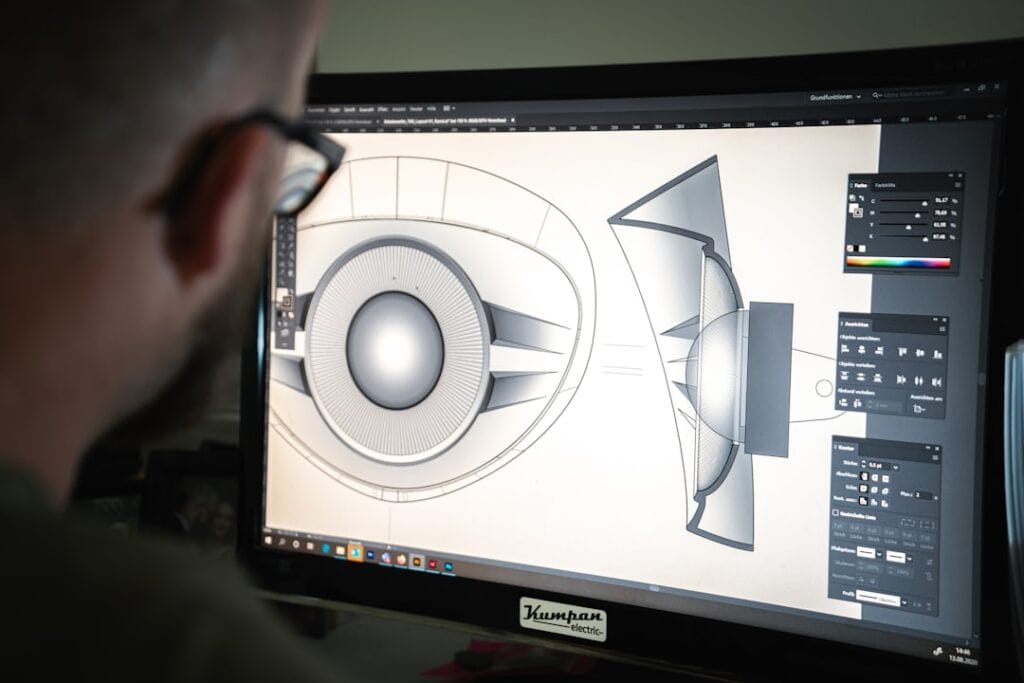

Next, designers create detailed sketches and digital models. These visual representations are crucial for transforming abstract ideas into tangible plans. They allow clients to visualize their future products clearly.

Finally, the manufacturer refines these designs through rigorous testing and feedback loops. This iterative process helps iron out any discrepancies, ensuring the final product perfectly matches the client’s expectations and functional requirements.

Custom Manufacturing vs. Mass Production

Custom manufacturing focuses on flexibility and individuality. It produces tailored solutions that meet specific customer requirements. Each product is unique, crafted to fit particular needs.

In contrast, mass production emphasizes uniformity and efficiency. It involves creating large quantities of identical products. This approach is often cost-effective but lacks personalization.

While mass production suits high-demand items, custom manufacturing excels in niche markets. It provides businesses with the opportunity to stand out by offering bespoke products. This enables greater market differentiation and customer satisfaction.

The Role of Custom Manufacturing Companies

Custom manufacturing companies are crucial for turning ideas into tangible products. They possess the expertise and technology needed to bring unique visions to life. Their involvement transforms concepts into practical solutions.

These companies act as partners rather than mere service providers. They work closely with clients to understand their specific needs and goals. This collaboration ensures that the final product aligns perfectly with the initial vision.

Additionally, custom manufacturers handle various technical aspects of production. From material selection to quality control, they ensure high standards are met. Their role is pivotal in delivering a product that stands out in quality and design.

Custom Manufacturing Examples Across Industries

Custom manufacturing is widely used across different industries. In the automotive sector, it allows for the creation of unique parts tailored to specific vehicle models. This customization enhances both performance and aesthetics.

In electronics, custom manufacturing plays a vital role in developing specialized components. These components enable advancements in technologies such as smartphones and wearable devices. This customization caters to unique user needs.

The fashion industry also benefits from custom manufacturing. It allows designers to produce exclusive pieces that match specific consumer tastes. This not only differentiates brands but also provides a personal touch to their offerings.

Advantages of Custom Product Manufacturing

Custom product manufacturing offers numerous advantages. It allows businesses to create products that stand out in a crowded market. This differentiation is crucial for attracting and retaining customers.

Businesses can respond flexibly to customer demands with custom manufacturing. It enables modifications based on feedback, ensuring customer satisfaction and loyalty. This adaptability is a competitive edge.

Cost-effectiveness is another benefit. While initial expenses might be higher, tailored products often lead to better market performance. Streamlined production can also reduce material waste, generating long-term savings.

Stages of Custom Production

Custom production begins with an in-depth design phase. This step involves refining ideas and creating detailed blueprints. It is crucial for aligning the final product with the client’s vision.

Next is prototyping, where a tangible model is crafted. This stage allows for testing and adjustments before mass production. It ensures the design works in real-world conditions.

The final stage is production itself. During this phase, the custom manufacturing company manufactures the product to meet quality standards. Continuous monitoring ensures that each item is made precisely and consistently.

Selecting the Right Custom Manufacturing Company

Choosing the right custom manufacturing company is crucial for success. The first step is to evaluate their expertise in your specific industry. This ensures they understand your unique requirements and challenges.

Another important factor is the company’s communication and collaboration skills. Effective communication helps in smoothly translating your vision into a finished product. Look for a partner who values transparency and keeps you informed at every stage.

Additionally, assess their quality control processes. Reliable custom manufacturing companies prioritize delivering high-quality results consistently. This commitment guarantees your products meet exact standards and expectations.

The Future of Custom Manufacturing

As technology advances, custom manufacturing is set to evolve dramatically. Innovations like 3D printing and AI are driving efficiencies in production. These technologies enable faster turnaround times and reduced waste.

Sustainability is also a growing focus in the custom manufacturing sector. Companies are adopting eco-friendly practices and materials. This shift addresses both consumer demand and regulatory pressures.

Furthermore, custom manufacturing will likely see more personalization trends. Customers increasingly seek products tailored to their specific needs. As a result, businesses will have to adapt quickly to meet these expectations.

Conclusion: Leveraging Custom Manufacturing for Business Success

Custom manufacturing offers unparalleled opportunities for business growth. By embracing this approach, companies can create unique products that stand out.

This flexibility allows businesses to respond swiftly to market changes. As a result, custom manufacturing becomes a powerful tool in building a competitive edge.

Contact Us