“Our Engineering CAD & Prototyping services turn product concepts into manufacturable designs. We use advanced 3D CAD modeling, engineering analysis, and prototype development to refine consumer product design and ensure production-ready results.

”

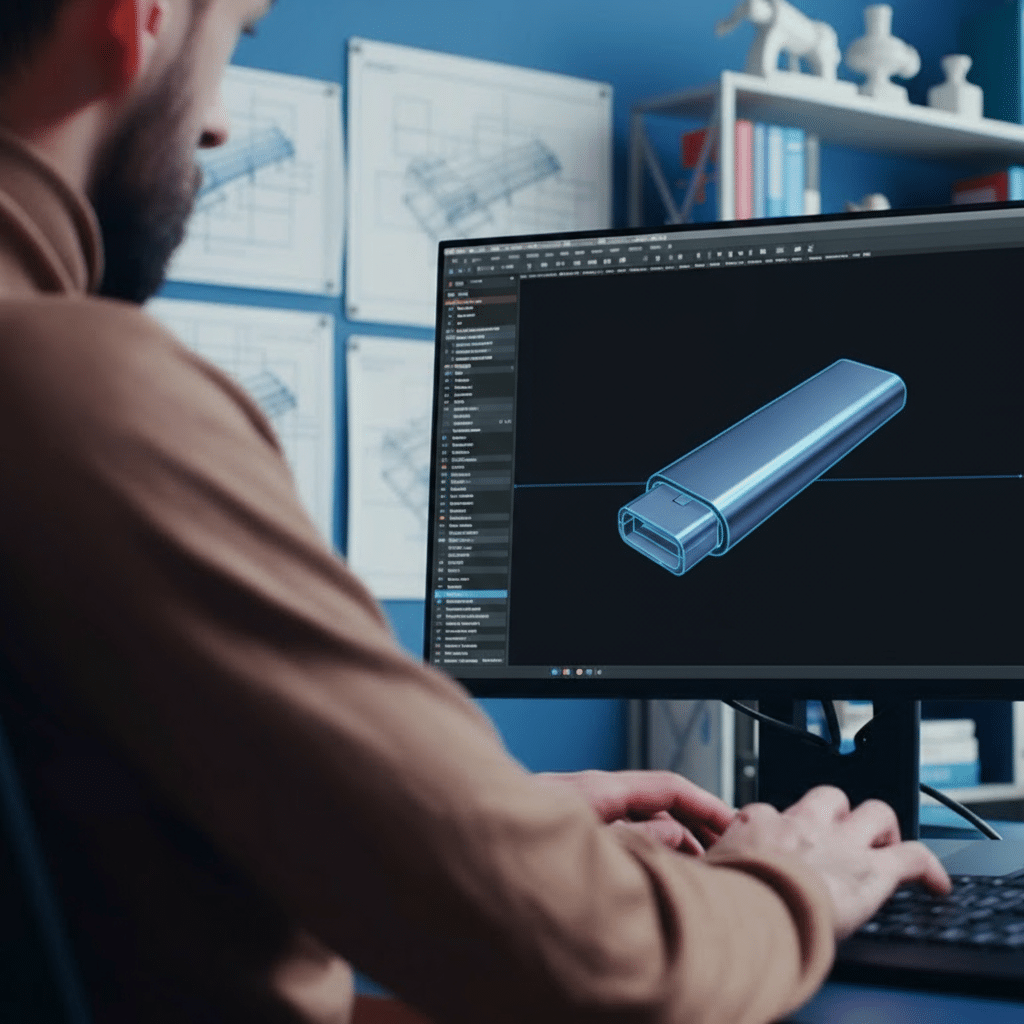

CAD Design and Engineering Analysis

The design refinement process begins with advanced Computer-Aided Design (CAD) software, where our engineering team meticulously develops digital models of the product concept. Using 3D CAD tools, we transform initial sketches and ideas into highly detailed models, capturing every aspect of the product’s geometry, mechanics, and functionality. This step ensures that the product not only meets design specifications but is also optimized for manufacturing.

Our engineering analysis focuses on ensuring structural integrity, material suitability, and design feasibility. If the product calls for it, we can conduct simulations such as stress testing, thermal analysis, and motion studies to identify and resolve potential issues early in the development process. This helps us fine-tune the design to optimize performance while minimizing production costs and potential risks.

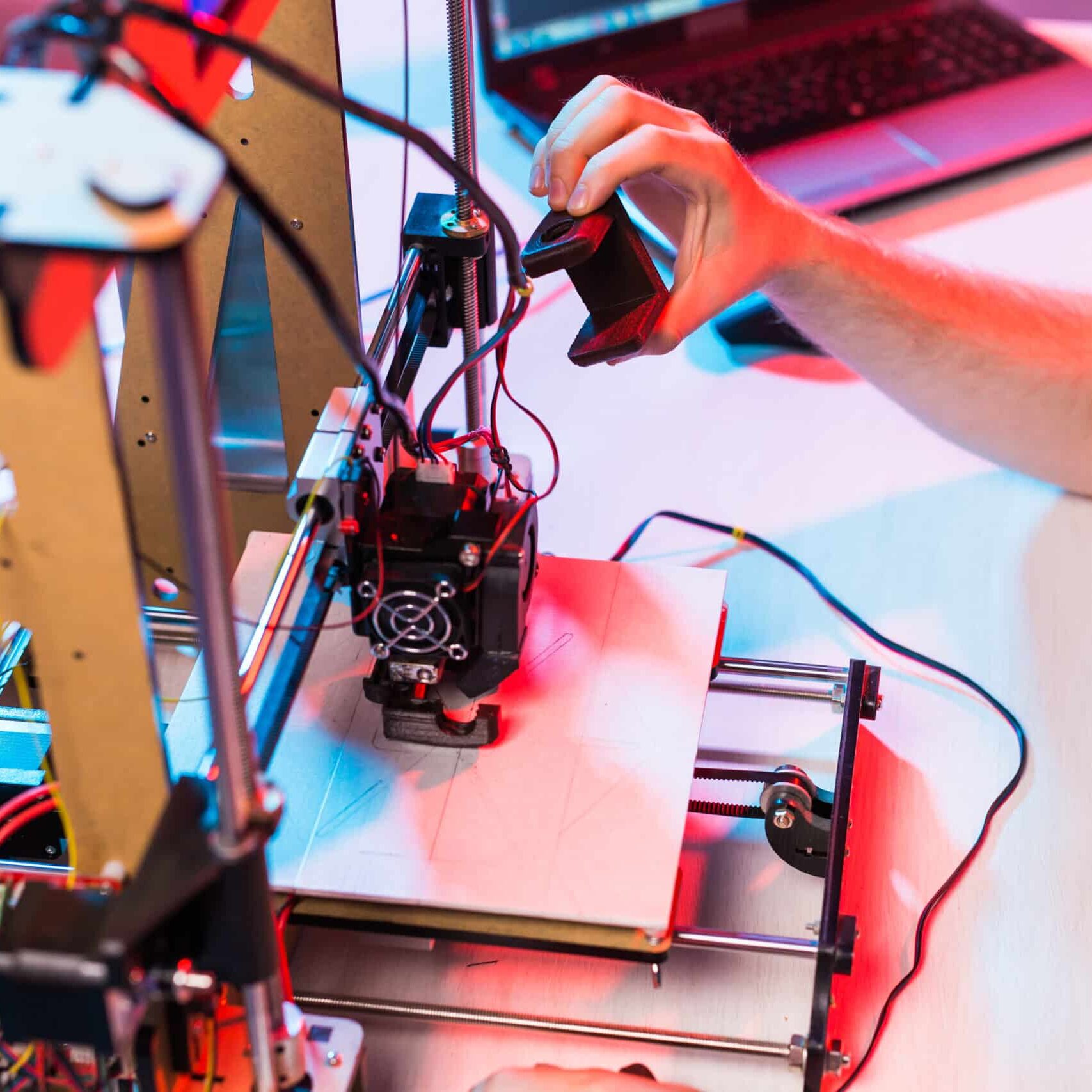

Prototype Production

Once the CAD model has been refined and approved, we move into the prototype production phase. We offer a range of prototyping services, depending on the product’s complexity and the client’s needs. Whether through 3D printing, CNC machining, or more rudimentary processes like simple handmade sampling techniques, our goal is to create a tangible version of the product that can be tested, analyzed, and further refined.

Prototypes allow clients to physically interact with their product, offering a real-world representation of what was initially developed in CAD. This tangible model provides invaluable insights into the product’s form, function, and user experience.

Prototype Analysis and Testing

After prototypes are built, we perform in-depth analysis and testing to ensure your product meets design specifications and real-world performance demands. This phase verifies durability, functionality, and ergonomics, while our team refines the design so the final product exceeds technical and market expectations.

Prototype feedback is essential — giving both your team and ours a hands-on way to confirm performance and usability. We make strategic revisions and optimize the design for efficient, cost-effective manufacturing.

Our Design for Manufacturing (DFM) services prepare your product for mass production. We analyze manufacturability, refine industrial tooling, and recommend the most effective production methods to control costs, speed time-to-market, and preserve design integrity and quality standards.